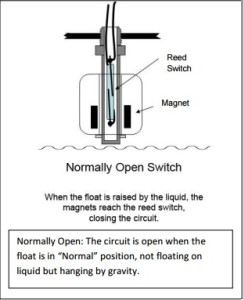

Float switches, along with other point degree sensors, are great options to the more costly continuous degree sensors. Functionally, needless to say, they are much less capable. However, they function great beneath the right conditions and continue being a staple in degree measurement applications across the world.

WHEN TO USE

The right time and energy to work with Level sensor s linked with the application objectives. What will the sensor do? If the solution to that query is merely to execute repeatable actions at a particular and steady level, a float switch simply can be a good sensor.

For instance, one major client of ours needed a custom made level sensors sensor with four normally open up floats. These floats basically start four lights because the level rises to point a rudimentary degree indication.

A more common software is raising the station pump handle. A good start station pumps drinking water or wastewater out of a wet properly to a higher floor where gravity can continue steadily to have it down the road. Wire suspended float switches can be used to start a pump because of the level inside the wet good rises. For larger raise stations, there are many pumps, each fired up by a single change activated as the degree rises faster compared to the previous pump are designed for.

The examples above represent common point degree sensor usage. Nevertheless, if the sensor must do more than merely initiate actions at a particular level, a float switch no more makes sense. Exactly the same is true for just about any point level technology.

YOU SHOULD DEFINITELY TO USE

Continuous levels of sensors supply the most versatility. These sensors can be utilized to achieve all the tasks a point degree sensor may, but with a number of added benefits.

You should understand it’s time to choose a continuous level sensor once you become worried about the accuracy of an event or perhaps a volume measurement, or when switching to a continuing sensor can spend less or increase efficiency.

Point level sensors are usually inadequate for degree measurement or supervising. They basically activate notifications, alarms, or control measures to help keep liquid degree within pre-described boundaries. They cannot give measurements or supply the advanced handle that depends on real-time data.

Applications that not need a continuous degree sensor may still reap the benefits of having one. Among this is the growth of pumps with an adjustable speed electric motor. These pumps are managed by way of a continuous degree sensor, and operate as fast or sluggish as needed – instead of basically on or off. This will save energy, is green, and will often lead to quick profits on return.

Float switches, along with other point degree switches, are excellent for the simple handle and cost a lower amount than continuous measurement. Nevertheless, it’s vital that you study the application and the devices that may improve your procedure. You might be able to update earlier than you think.